Injin sake yin amfani da Filastik nau'in kayan aiki ne da ake amfani da shi don sarrafa sharar gida ko zubar da robobi a cikin ɓangarorin filastik da za a sake amfani da su. Yana narkar da kayan filastik da aka yi amfani da su kamar PE, PP, ko PET kuma ya sake fasalin su zuwa ƙananan ƙananan pellets iri ɗaya ta hanyar extrusion da yanke.

Wannan na'ura tana taka muhimmiyar rawa wajen sake sarrafa robobi ta hanyar juya robobin da aka jefar zuwa albarkatun kasa don sabbin kayayyaki. Yana taimakawa rage gurɓatar filastik, rage farashin samarwa, kuma yana tallafawa masana'antu masu dorewa a cikin masana'antu kamar marufi, gini, da kayan masarufi.

Fahimtar fasali, ribobi da fursunoni, da yuwuwar aikace-aikace na Injin Maimaita Filastik na Filastik zai taimaka muku yanke shawara mafi kyau kuma zaɓi madaidaicin granulator ko haɗin kai don biyan bukatun masana'anta.

Ci gaba da karantawa yayin da muke dalla-dalla dalla-dalla injunan sake yin amfani da filastik daban-daban da kuma samar da ɗan gajeren jagora a ƙarshen labarin don zaɓar mafi kyawun granulator don aikin ku.

Nau'o'inInjin sake amfani da Filastik

Na'urorin sake amfani da Filastik na zamani an ƙera su tare da ingantattun tsarin makamashi, sarrafa zafin jiki na atomatik, da haɓakar tacewa don tabbatar da ingancin granules. Ana amfani da su sosai a cikin sake amfani da tsire-tsire, masana'antar samfuran filastik, da cibiyoyin sarrafa muhalli don ɗaukar nau'ikan sharar filastik, daga fim da kwalabe zuwa sassa na allura.

Na gaba, zamu tattauna a taƙaice nau'ikan nau'ikan granulators 12 daban-daban.

1. Recycling compactor granulation line

Layin Recycling Compactor Granulation Line cikakke ne da ake amfani da shi don sarrafa sharar filastik masu nauyi-kamar fina-finai, jakunkuna da aka saka, da kayan kumfa-zuwa cikin manyan pellet ɗin filastik. Yana haɗa haɗakarwa, extrusion, tacewa, da pelletizing cikin tsari guda ɗaya mai ci gaba. Compactor ya riga ya matsa kayan laushi ko babba, yana sauƙaƙa ciyar da su cikin fiɗa ba tare da gada ko toshe ba.

Amfani

Ingantacciyar Ciyarwa: Ƙaƙwalwar da aka gina a ciki tana aiwatar da haske da kayan miya, yana hana toshewar ciyarwa.

Tsarin Haɗaɗɗen: Haɗa haɗakarwa, extrusion, tacewa, da pelletizing a cikin layi ɗaya mai ci gaba.

Sarari & Ajiye Aiki: Ƙirar ƙira tare da babban aiki da kai yana rage buƙatar aikin hannu da sararin masana'anta.

Faɗin Material Daidaitawa: Yana ɗaukar robobi masu laushi daban-daban kamar fim ɗin PE/PP, jakunkuna da aka saka, da kayan kumfa.

Daidaitaccen Ingantacciyar Pellet: Yana samar da nau'ikan nau'ikan filastik da suka dace don sake amfani da su a samarwa.

Rashin amfani

Bai Dace da Filastik ɗin Hard: Ƙaƙƙarfan robobi ko tsayayyen robobi (misali, sassan allura, kwalabe) na iya buƙatar wasu injuna.

Ana Bukatar Tsaftar Kayan Abu: Babban danshi ko matakan gurɓatawa (kamar datti ko takarda) na iya shafar aiki da ingancin pellet.

Ana Buƙatar Kulawa Na Kai-da-kai: Ƙaƙƙarfan ƙwanƙwasa da wuraren tacewa suna buƙatar tsaftacewa na lokaci-lokaci don tabbatar da ingantaccen aiki.

Aikace-aikace

Sake amfani da Fim ɗin Noma: Don fim ɗin ciyawa na PE, fim ɗin greenhouse, da sauran robobin sharar gonaki.

Marubucin Filastik na Bayan-Mabukaci: Mafi dacewa don sarrafa buhunan siyayya, fim mai shimfiɗa, jakunkuna na isar da sako, da sauransu.

Farfado da Scrap Masana'antu: Yana sake sarrafa sharar da ake samarwa daga masana'antun fim da saƙa.

Tsire-tsire masu sake amfani da Filastik: Mafi dacewa don wuraren sarrafa manyan ɗimbin sharar filastik mai laushi.

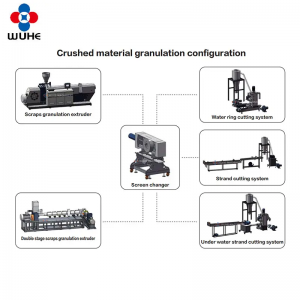

2.Crushed abu granulation line

Layin Granulation Abun da aka Crushed tsarin sake yin amfani da filastik ne wanda aka ƙera don sarrafa sharar robo mai wuya wanda tuni an yayyage ko ya niƙasa ya zama flakes. Wannan ya haɗa da kayan kamar HDPE, PP, PET, ABS, ko PC daga kwalabe, kwantena, da tarkacen masana'antu. Layin yawanci ya haɗa da tsarin ciyarwa, guda ɗaya ko twin-screw extruder, sashin tacewa, tsarin pelletizing, da sashin sanyaya/ bushewa.

Amfani

Ciyarwar Kai tsaye na Kayayyakin Rushe: Babu buƙatar pre-compaction; dace da robobi masu tsauri kamar kwalabe, kwantena, da sassan allura.

Stable Output: Yana aiki da kyau tare da uniform, m kayan, samar da m extrusion da pellet ingancin.

Babban Haɓakawa: Ƙirar ƙira mai ƙarfi da ingantaccen tsarin tsagewa yana haɓaka narkewa da rage matsalolin danshi.

Kanfigareshan Mai sassauƙa: Ana iya sanye shi da masu fitar da matakai guda ɗaya ko tagwaye, zoben ruwa ko pelletizers dangane da nau'in kayan.

Yana da kyau don Tsabtace Tsabtace: Musamman tasiri lokacin sarrafa tsaftataccen, rarrabuwar filayen filastik daga layin wanka.

Rashin amfani

Ba Madaidaici ba don Filastik mai laushi ko Fluffy: Kayan haske kamar fina-finai ko kumfa na iya haifar da rashin kwanciyar hankali ko haɗawa.

Yana buƙatar wanke-wanke: Abubuwan datti ko gurɓatattun abubuwa suna buƙatar tsaftacewa sosai kafin granulation.

Ƙananan Dace da Filastik Haɗe-haɗe: Daidaitaccen abu yana shafar ingancin pellet; gauraye nau'ikan polymer na iya buƙatar haɗawa ko rabuwa.

Aikace-aikace

Recycling Plastic Recycling: Don kwalabe na HDPE/PP, kwantena shamfu, ganga na wanka, da sauransu.

Rubutun Filastik Bayan Masana'antu: Ya dace da ragowar da aka daka daga gyaran allura, extrusion, ko gyaran fuska.

Filayen da aka wanke daga Layin Maimaitawa: Yana aiki da kyau tare da tsabtace PET, PE, ko PP flakes daga tsarin wanke kwalban.

Samfuran Pellet Filastik: Mafi dacewa ga masana'antun suna canza tsaftataccen regrind zuwa pellet ɗin sake amfani da su don allura ko extrusion.

3. Saƙa jakar jakar sake amfani da pelletizing layi

Layin Pelletizing Bag Sake Sake Sake-sake, tsarin sake yin amfani da shi ne na musamman da aka ƙera don sarrafa PP (polypropylene) jakunkuna da aka saka, raffia, jakunkuna na jumbo (FIBCs), da sauran irin kayan masakun roba. Waɗannan kayan yawanci marasa nauyi ne, masu jurewa hawaye, kuma suna da wahalar ciyarwa kai tsaye cikin tsarin pelletizing na gargajiya saboda ƙaƙƙarfan tsarinsu. Wannan layin yana haɗe da murkushewa, haɗawa, extrusion, tacewa, da pelletizing zuwa ci gaba da tsari wanda ke canza kayan filastik saƙa da aka yi amfani da su zuwa pellet ɗin filastik iri ɗaya.

Wannan bayani shine manufa don sake yin amfani da sharar marufi da aka saka bayan masana'antu da masu amfani da su, yana taimakawa rage gurɓatar muhalli da sake haɓaka albarkatun ƙasa don masana'antar filastik.

Amfani

Haɗin Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa ) yana daɗaɗa nauyi, kayan saƙa don tabbatar da ciyar da abinci mai santsi da kwanciyar hankali a cikin extruder.

Babban inganci: An tsara shi don aiki mai girma tare da ci gaba da aiki da ƙananan buƙatun ma'aikata.

Dorewa da Tsayayyen Fitarwa: Yana samar da pellets iri ɗaya tare da kyawawan kaddarorin inji, dacewa don sake amfani da ƙasa.

Hannun Kayayyakin Kalubale: An gina musamman don ɗaukar jakunkuna saƙa, jakunkuna na jumbo tare da layukan layi, da sharar raffia.

Zane na Musamman: Mai iya daidaitawa tare da yankan daban-daban, rarrabawa, da tsarin tacewa waɗanda aka keɓance da yanayin kayan daban-daban.

Rashin amfani

Ana Bukatar Magani Sau da yawa: Jakunkuna masu datti na iya buƙatar wankewa da bushewa kafin a sake yin amfani da su don kula da ingancin pellet.

Babban Amfani da Makamashi: Saboda ƙaddamarwa da narkewar kayan aiki mai yawa, tsarin zai iya cinye ƙarin iko.

Material Sensitivity: Rashin daidaiton kauri ko zaren dinki na iya shafar ciyarwa da kwanciyar hankali.

Aikace-aikace

Sake yin amfani da PP Buhunan Saƙa: Mafi dacewa ga buhunan siminti, buhunan shinkafa, buhunan sukari, da jakunkunan ciyarwar dabbobi.

Jumbo Bag (FIBC) Sake sarrafawa: Ingantaccen Magani don sake yin amfani da manyan kwantena masu sassauƙa na matsakaici.

Sake yin amfani da Yadi da Sharar Raffia: Ya dace da masana'antun saƙa da samfuran raffia don sake fa'ida datsa da tarkace.

Samar da Pellet Filastik: Yana samar da ingantattun granules na PP don sake amfani da su a cikin gyaran allura, extrusion, ko busa fim.

4.EPS/XPS Granulation Line

Layin Granulation na EPS/XPS ƙwararren tsarin sake yin amfani ne da aka ƙera don aiwatar da faɗaɗa polystyrene (EPS) da sharar kumfa polystyrene (XPS) zuwa cikin granules na filastik da za a sake amfani da su. EPS da XPS masu nauyi ne, kayan kumfa da aka saba amfani da su a cikin marufi, rufi, da gini. Saboda girman yanayinsu da ƙarancin ɗimbin yawa, suna da wahala a iya amfani da su ta amfani da kayan aikin gyaran filastik na al'ada. Wannan layin granulation yawanci ya haɗa da murkushewa, ƙaddamarwa (narkewa ko haɓakawa), extrusion, tacewa, da tsarin pelletizing.

Babban manufar wannan layin shine don rage girma, narke, da sake sarrafa sharar kumfa EPS/XPS zuwa cikin nau'ikan nau'ikan polystyrene (GPPS ko HIPS), waɗanda za'a iya sake amfani da su a masana'antar filastik.

Amfani

Rage girma: Tsarin compactor ko densifier yana rage girman kayan kumfa sosai, inganta ingantaccen ciyarwa.

Babban Fitarwa tare da Kayayyakin Haske: An ƙirƙira ta musamman don ƙarancin kumfa, tabbatar da ingantaccen ciyarwa da ci gaba da extrusion.

Zane-zanen Screw Saving Energy: Ingantaccen tsarin dunƙule da tsarin ganga yana tabbatar da ingantaccen narkewa tare da rage yawan kuzari.

Abokan Muhalli: Yana taimakawa rage sharar ƙasa kuma yana goyan bayan yin amfani da madauwari na marufi da kayan rufewa.

Fitar da za a iya sake yin amfani da su: Granules ɗin da aka samar sun dace don sake amfani da su a aikace-aikacen da ba abinci ba kamar zanen rufi ko bayanan bayanan filastik.

Rashin amfani

Yana buƙatar Kumfa mai Tsafta da bushewa: EPS/XPS dole ne su kasance masu 'yanci daga mai, abinci, ko ƙazanta mai nauyi don kula da ingancin pellet.

Ana Bukatar Kula da Wari da Fume: Narke kumfa na iya sakin hayaki; iskar iskar da ta dace ko tsarin shayewa suna da mahimmanci.

Bai Dace da Filastik ɗin Haɗaɗɗen: An inganta tsarin don EPS/XPS mai tsabta; gauraye kayan na iya toshe ko ɓata ingancin fitarwa.

Aikace-aikace

Marufi Maimaita Kumfa: Mafi dacewa don sake amfani da farar fakitin EPS da ake amfani da su a cikin kayan lantarki, kayan aiki, da kayan daki.

Farfadowa Kayan Aikin Gina: Ya dace da tarkacen allo na XPS daga rufin gini da bangon bango.

Gudanar da Sharar Factory Factory: Masu masana'antun samfuran EPS/XPS ke amfani da su don sake yin amfani da datsa gefen samarwa da ɓangarorin da aka ƙi.

Polystyrene Pellet Production: Yana canza sharar kumfa zuwa GPPS/HIPS granules don aikace-aikace na ƙasa kamar zanen filastik, rataye, ko samfuran gyare-gyare.

5. Parallel Twin Screw Granulation Line

Layin Layin Twin Screw Granulation Tsarin layi shine tsarin sarrafa filastik wanda ke amfani da sukurori guda biyu masu kama da juna don narke, gauraya, da pelletize kayan filastik daban-daban. Idan aka kwatanta da masu fitar da dunƙule guda ɗaya, tagwayen sukurori suna samar da ingantacciyar haɗuwa, mafi girma fitarwa, da iko mafi girma akan yanayin sarrafawa. Wannan tsarin ya dace musamman don sake yin amfani da robobi masu gauraye, da haɗa abubuwan da ake ƙarawa, da kuma samar da ingantattun granules na filastik tare da ingantattun kaddarorin.

Layin gabaɗaya ya ƙunshi tsarin ciyarwa, mai daidaita tagwayen dunƙulewa, sashin tacewa, pelletizer, da sashin sanyaya/ bushewa, wanda aka ƙera don ci gaba da aiki mai tsayi.

Amfani

Babban Haɗawa da Haɗawa: Twin sukurori suna ba da kyakkyawan haɗin kai, yana ba da damar haɗuwa da polymers daban-daban da ƙari.

Babban Fitarwa da Ingantawa: Yana ba da mafi girma fitarwa da ingantaccen tsarin aiki idan aka kwatanta da masu fitar da dunƙule guda ɗaya.

Sarrafa Maɓalli Mai Yawa: Ya dace don sarrafa nau'ikan robobi, gami da PVC, PE, PP, ABS, da robobin da aka sake sarrafa su.

Ingantattun Sarrafa Tsari: Gudun dunƙule masu zaman kansu da wuraren zafin jiki suna ba da damar daidaitaccen daidaitawa don ingantaccen ingancin pellet.

Ingantaccen Degassing: Ingantaccen cire danshi da rashin ƙarfi, yana haifar da tsaftataccen pellets.

Rashin amfani

Zuba Jari na Farko mafi girma: Tsarin dunƙule tagwaye gabaɗaya sun fi tsada don siye da kulawa fiye da masu fitar da dunƙule guda ɗaya.

Hadaddiyar Aiki da Kulawa: Yana buƙatar ƙwararrun masu aiki da kulawa akai-akai don kiyaye sukurori da ganga cikin kyakkyawan yanayi.

Ba Ma'auni ba don Abubuwan Maɗaukakin Danko Na Musamman: Wasu kayan ƙwanƙwasa na iya buƙatar kayan aiki na musamman ko yanayin sarrafawa.

Aikace-aikace

Sake yin amfani da filastik: Yana da tasiri don sake sarrafa cakuɗen dattin filastik cikin ɓangarorin iri ɗaya don sake amfani.

Haɗawa da Samar da Masterbatch: Ana amfani da shi sosai wajen samar da mahadi na filastik tare da filaye, masu launi, ko ƙari.

PVC da Injiniyan Filastik Processing: Mafi dacewa don sarrafa zafi-m da hadaddun polymers.

Ƙirƙirar Material Mai Girma: Ana amfani da shi wajen samar da robobi na musamman tare da keɓaɓɓen kayan aikin injiniya ko sinadarai.

Mabuɗin Mahimmanci don Zaɓin Mafi Kyau Nau'in Injin Maimaita Filastik

Masu biyowa wasu mahimman la'akari ne don zaɓin Injin Maimaita Filastik wanda zai iya biyan bukatun masana'anta.

1. Sanin Nau'in Kayan Ku

Filastik masu laushi (misali, fim, jakunkuna, kumfa): Zaɓi na'ura tare da maɗaukaki ko maɗaukaki don tabbatar da ciyarwa da kyau.

Filastik mai wuya (misali, kwalabe, kwantena masu ƙarfi): Layin ƙwanƙwasa kayan abu tare da bargaciyar ciyarwa ya fi dacewa.

Filayen Cakuɗi ko Gurɓataccen Filastik: Yi la'akari da tagwayen screw extruders tare da ƙarfin haɗawa da ƙarfin tacewa.

2. Tantance Ƙarfin Abubuwan Bukatun

Yi ƙididdige girman aikin yau da kullun ko kowane wata.

Zaɓi samfurin da ya dace da abin da kuke so (kg/h ko tons/day) don gujewa ƙaranci ko fiye.

Don sake yin amfani da babban sikelin, babban fitarwa tagwaye-screw ko tsarin matakai biyu sun dace.

3. Bincika Bukatun Ciyarwa & Kafin Magani

Shin kayan ku na buƙatar wankewa, bushewa, ko murƙushewa kafin granulation?

Wasu injuna sun haɗa da haɗe-haɗen shredders, washers, ko compactors. Wasu suna buƙatar kayan aiki na waje.

Kayan datti ko rigar suna buƙatar tsarin tsattsauran ra'ayi mai ƙarfi da narke tacewa.

4. Yi la'akari da ingancin Pellet na ƙarshe

Don manyan aikace-aikace (misali busa fim, gyare-gyaren allura), daidaitaccen girman pellet da abu mai tsabta.

Injin da ke da madaidaicin sarrafa zafin jiki da masu canza allo ta atomatik suna samar da mafi tsabta, ƙarin nau'in granules.

5. Amfanin Makamashi & Automation

Nemo injuna masu inverter-sarrafawa inverter, makamashi ceton dumama, da PLC sarrafa kansa.

Tsarin sarrafa kansa yana rage farashin aiki kuma yana tabbatar da daidaiton ingancin samarwa.

6. Maintenance & Kayayyakin Tallafi

Zaɓi na'ura daga ma'auni mai dogara tare da sabis na amsawa da sauri, goyon bayan fasaha, da sassauƙan damar shiga.

Zane-zane masu sauƙi na iya rage raguwar lokaci da rage farashin kulawa na dogon lokaci.

7. Keɓancewa & Fadada Gaba

Yi la'akari da injuna masu ƙirar ƙira waɗanda ke ba da izinin haɓakawa (misali, ƙara fiɗa na biyu ko canza nau'in pelletizing).

Tsarin sassauƙan tsari yana dacewa da sababbin nau'ikan kayan aiki ko mafi girma yayin da kasuwancin ku ke girma.

Yi la'akari da injin WUHESabis na Injin Maimaita Filastik

A matsayin ƙwararrun masana'anta da fiye da shekaru 20 na gwaninta, WUHE MACHINE (Zhangjiagang Wuhe Machinery Co., Ltd.) ya yi fice a cikin ƙira, samarwa, da sabis na duniya na injinan sake yin amfani da filastik.

Tare da tsarin fiye da 500 da aka shigar kuma sama da tan miliyan 1 na filastik ana sarrafa kowace shekara-rage kimanin tan 360,000 na hayaƙin CO₂—WUHE ta tabbatar da ƙarfin fasaha da tasirin muhalli.

Takaddun shaida ta ISO 9001 da CE takaddun shaida, suna ba da hanyoyin haɗin kai don fim, jakar saƙa, EPS/XPS, filastik da aka murƙushe, da layin granulation na tagwaye. Tsananin ingancin su, ƙirar tsarin zamani, sassaucin OEM/ODM, da goyon bayan tallace-tallace masu dacewa suna tabbatar da cewa masu siyar da B2B sun sami ingantaccen inganci, ingantaccen aiki, da kuma keɓance hanyoyin sake yin amfani da su a duk duniya.

Zaɓi WUHE MASHIN don ingantaccen aiki, gyare-gyaren gyaran gyare-gyare na musamman, da amintaccen abokin tarayya don gina masana'antar robobi mai ɗorewa, mai ɗorewa.

Lokacin aikawa: Jul-01-2025