PP, PE, ABS, PS, HDPE, PP karya crushed abu sau biyu mataki sake yin amfani da granulation line inji.

Babban siga

Mai ɗaukar nauyi

Ya dace da hopper ciyar da extruder don gane sarrafawa ta atomatik.

Mai ciyarwa

● Kayan hopper: Bakin karfe; Hanyar ciyarwa: Ciyarwar dunƙule; Mai sarrafa Feeder: Mai jujjuyawar ke sarrafa shi.

Injin fitar da kaya

● Single dunƙule extruder tare da m iska m don inganta kayan quality.It sanye take da wani musamman zane na ganga da dunƙule da guda dunƙule shaye tsarin, iya tabbatar da high yawan amfanin ƙasa.

Vacuum iska mai gajiyar tsarin

● Ingantacciyar gajiyar iska don inganta ingancin kayan.

● Salon mai ban sha'awa: matattarar ruwa.

● Dakin Vacuum: zane na musamman.

● Vacuum cover farantin: aluminum gami.

● Vacuum tube: zafin jiki da juriya na bututun roba.

Mataki na granulation guda ɗaya da granulation mataki biyu an ƙaddara ta abu. A ƙasa akwai cikakkun bayanai na extruder mataki na biyu.

Baby extruder

● Extruder mai mataki biyu zai iya fitar da ruwa da datti daga kayan aiki yadda ya kamata, kuma ingancin barbashi ya fi kyau.

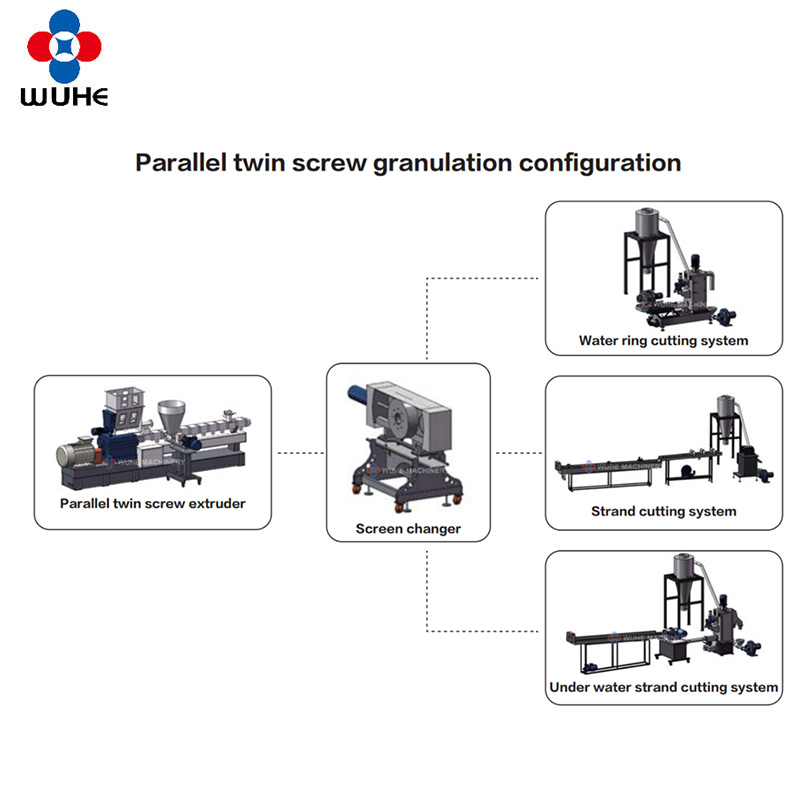

Mai canza allo

● Masu canza allo daban-daban suna biyan bukatun abokan ciniki daban-daban.

Muna da nau'ikan tsarin yankan pellet guda uku:

1. Tsarin yankan zobe na ruwa.

2. Tsarin yankan igiya.

3. Tsarin yankan igiyar ruwa na karkashin ruwa.

Dangane da halaye daban-daban na kayan abu, za mu ba da shawarar hanyoyin yankan daban-daban.

1. Tsarin yankan zobe na ruwa

● A sabon tsarin rungumi dabi'ar extrusion mutu shugaban ruwa zobe don yanke, wanda zai iya tabbatar da cikakken bayyanar barbashi.

Injin dewatering na Centrifugal

● Wannan na'ura yana da fa'idodi da yawa, irin su babban matakin bushewa, ƙarancin amfani da wutar lantarki, inganci mai ƙarfi, babban matakin sarrafa kansa, kuma yana rage ƙarfin aiki sosai. Rashin ruwa yana da tsabta, kuma yana iya wanke ƙananan yashi da ƙananan yashi a cikin pla.

2. Tsarin yankan Strand

● Don wasu kayan da ke da ɗanko mai ƙarfi, kamar PP, muna ba da shawarar amfani da hanyar yanke tsiri.

3. Tsarin yankan tsayawa karkashin ruwa

● Ya dace da manyan kayan narkewa, irin su PET da PP da sauransu.

● bushewar bututun iska

Ruwan da ke saman pellet ɗin yana ƙafewa ta hanyar ƙa'idar isar da bututun iska, kuma yana jigilar busassun pellets zuwa ma'ajiyar tattarawa, sannan don kulawa.

Tsarin sarrafa wutar lantarki

● PLC sarrafawa ta atomatik

Tsarin kayan abu